Hotline service:

+86 15322935130

Engineered for Control: The Platform for Precision

The DHT facility is the physical embodiment of our engineering-first philosophy. This 10,000 sqm vertically integrated environment is purpose-built to execute the validated manufacturing roadmaps we develop. Every zone, from material handling to final audit, is designed for traceability and stability, ensuring the precision defined in our engineering plans is realized in every component. Below is an overview of our core production capabilities.

CNC Center:

Makino 5 axis machining centers:D500 X 6, D300 X 4, D200X4,N2 X 1

Makino machining centers:V55 X 1, A51 X 1

5 Axis &Horizontal machining centers : GROB 5 Axis :G550, Kiwa Horizontal : KH-4500 ,Mazak 5 Axis : C600

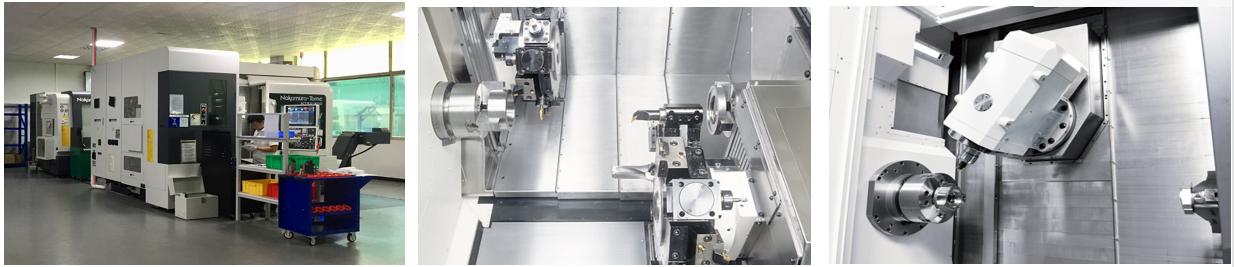

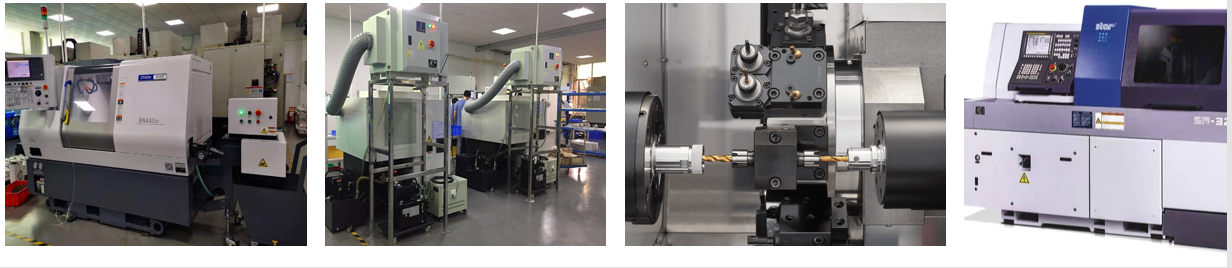

Turn-Mill Complex Machining Center

![]()

![]()

Nakamura-Tome: Turn-milling centers:WT300X1, NTRX300X1、BAN-42SY5X1WT300,NTRX,

CITIZEN BNA42sy X1, XKNC X 4,, STAR X 10,SWISS STAR

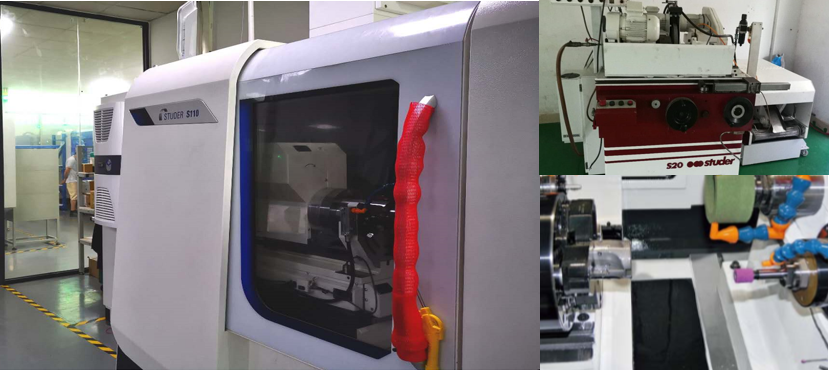

Grinding Machining Center

Swiss Studer

Modle:S20,S110,ECO650

Maximum grinding diameter: 230mm

Accuracy:0.0003mm

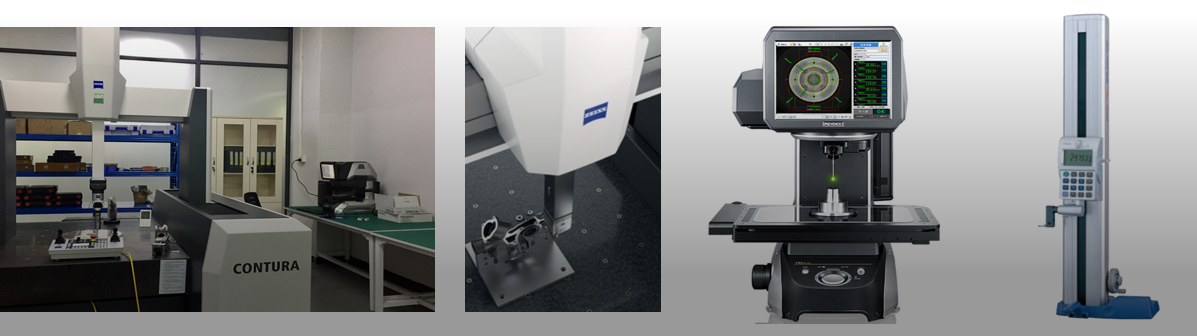

In-House Test Center

Equipments:

ZEISS CMM*3

Mitutoyo measuring instruments

Harness measuring machine

Profile test machine

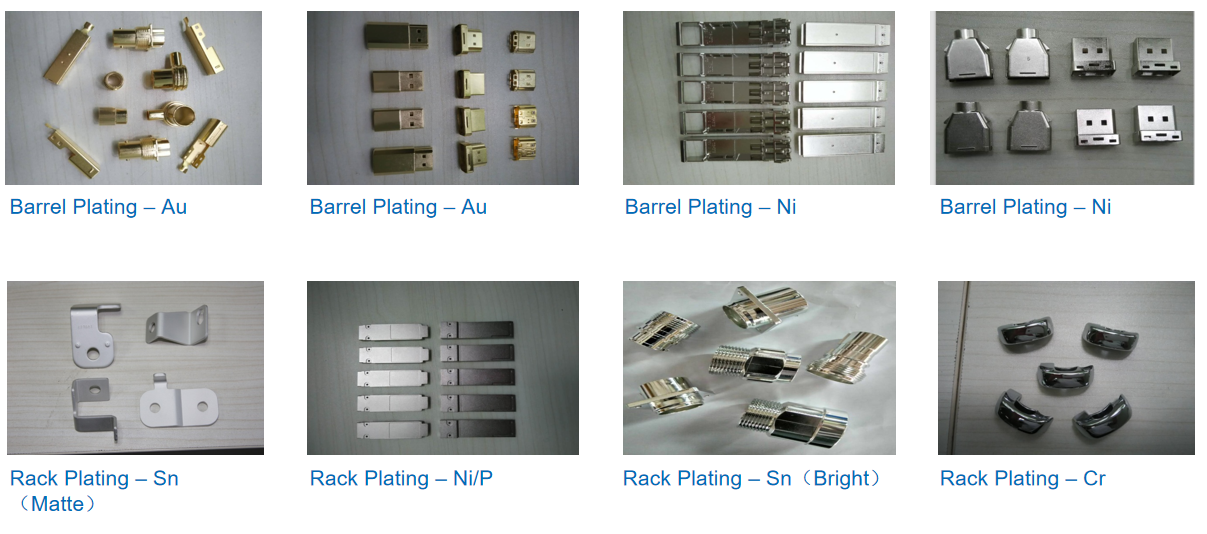

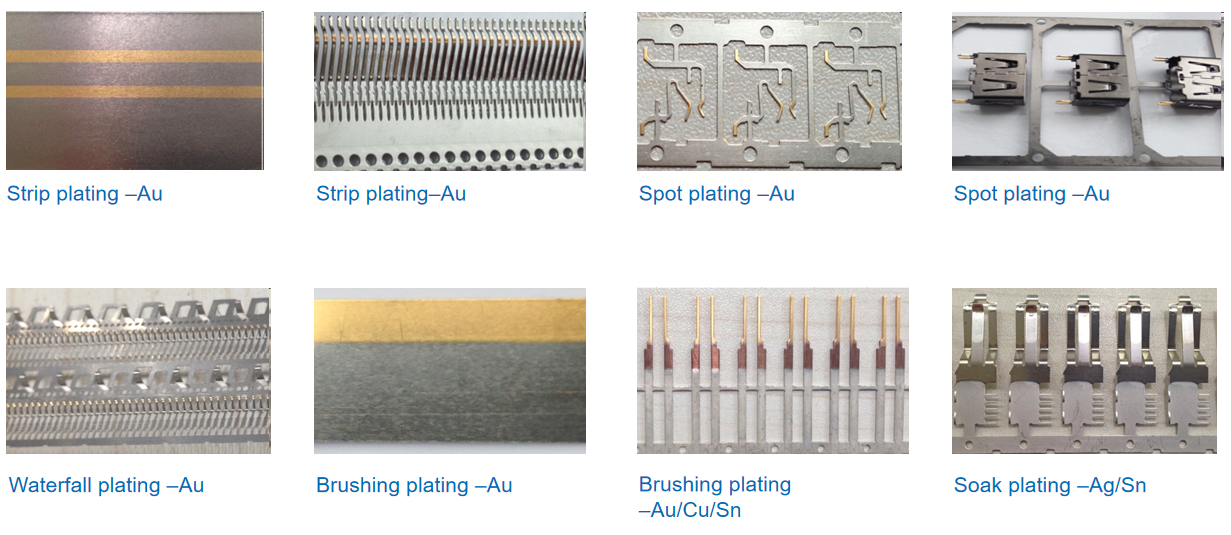

Plating Center- Roll Plating, Hang Plating&Continuous Plating

Certified by: ISO9001 ISO13485 ISO14000