precision stamping

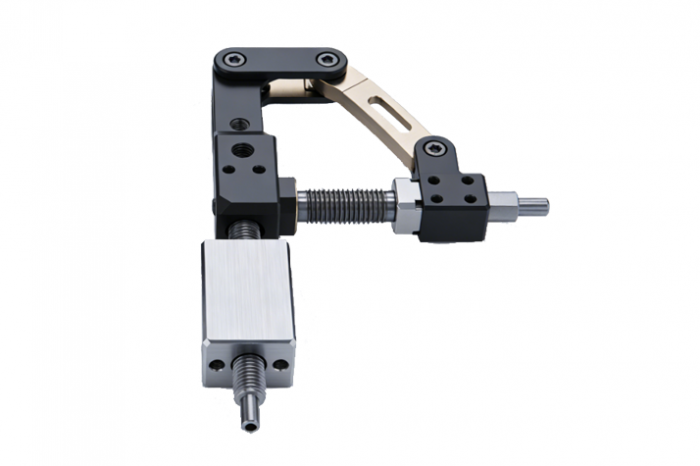

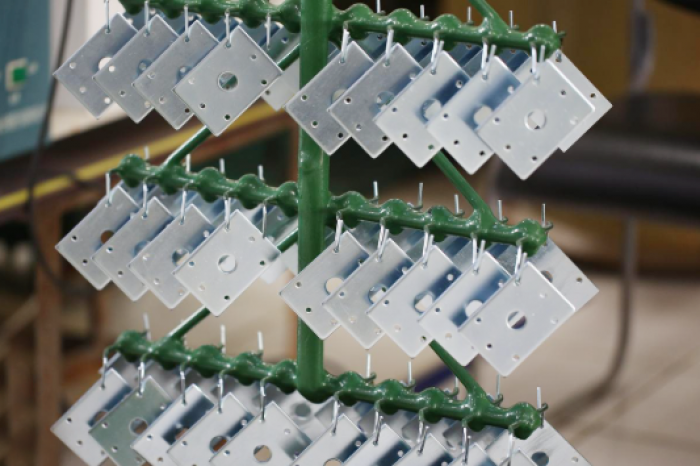

Custom high-accuracy stamped metal parts for electronics, medical devices, automotive, robotics, connectors, and industrial equipment.

Our precision stamping services cover both prototype and mass production, utilizing progressive dies, compound dies, and single-stage stamping. We specialize in stamping stainless steel, copper, aluminum, titanium, and specialty alloys to meet strict dimensional tolerances.

Stamped Electronic Components

Stamped Enclosures and Brackets

Terminal and Contact Parts

Stamped Heat Dissipation Panels

MORE